Introduction

Sanding discs are indispensable tools in various industries, including woodworking, metalworking, automotive, and DIY projects. Among the different sizes available, the 150mm sanding disc holds a significant position due to its versatility, efficiency, and effectiveness in achieving smooth surfaces. In this article, we will delve deep into the characteristics of 150mm sanding discs, exploring their composition, applications, advantages, and considerations for optimal use.

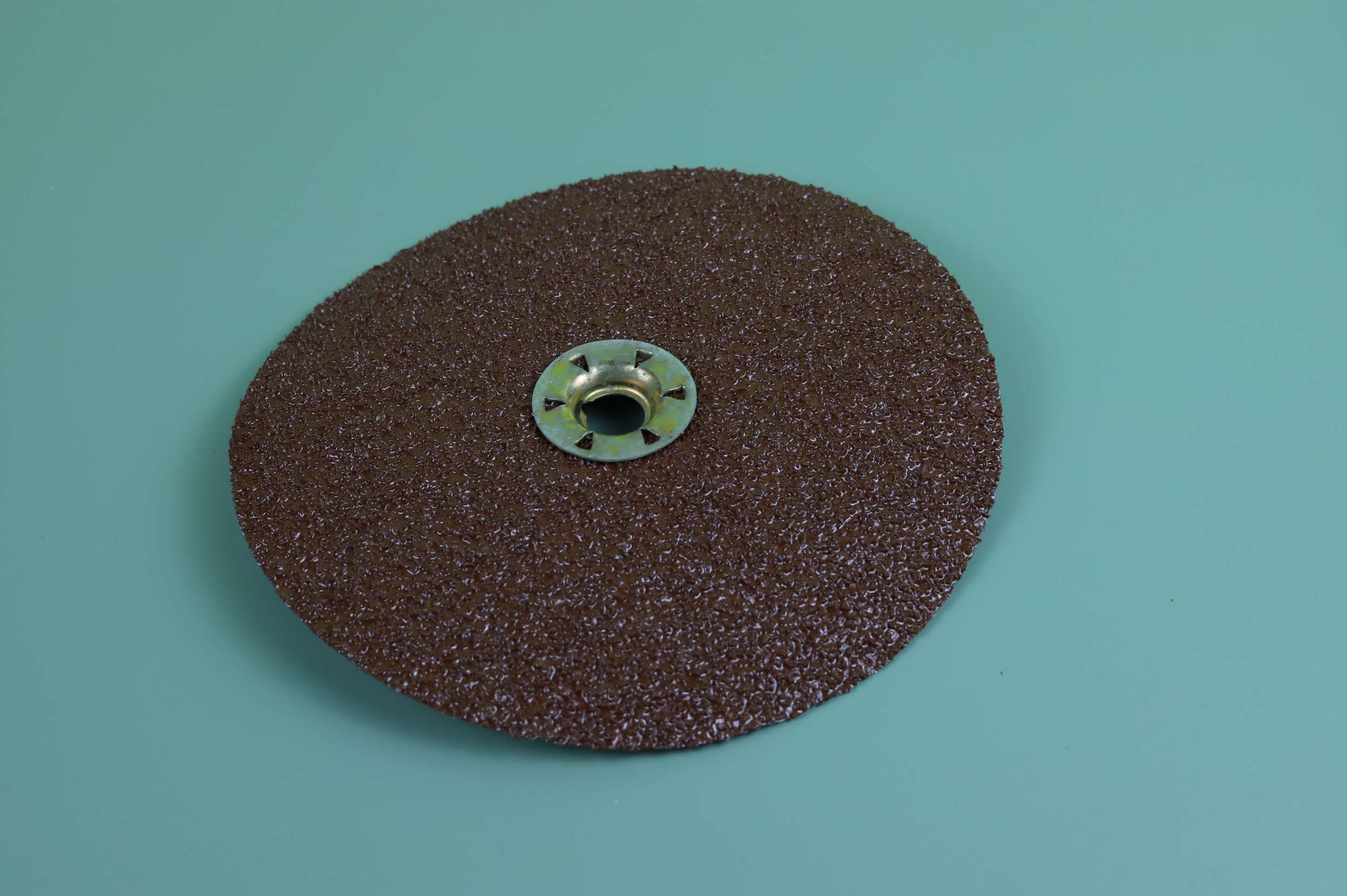

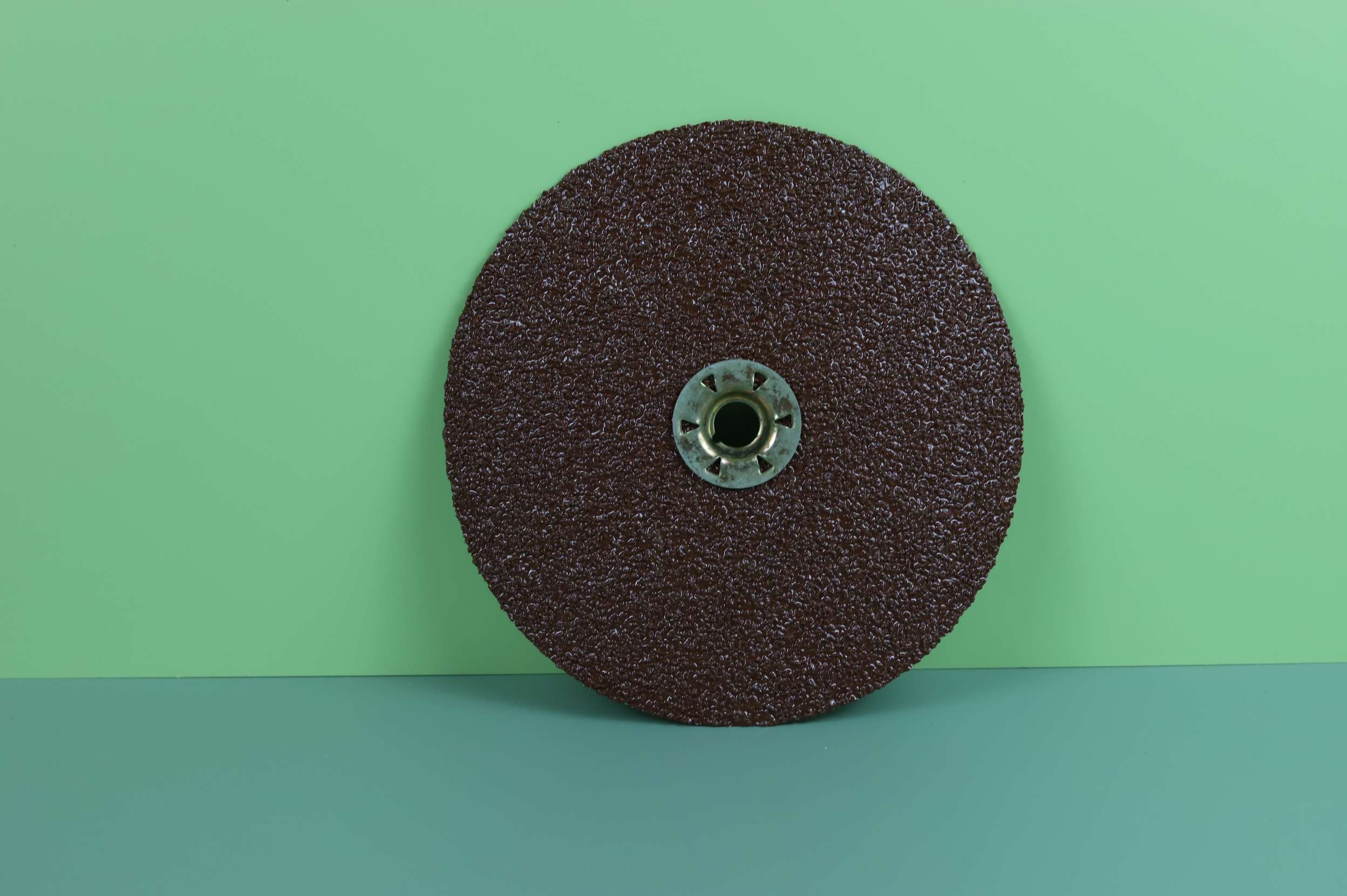

Composition and Design

150mm sanding discs are typically composed of several layers of abrasive material bonded to a sturdy backing material, such as paper, cloth, or film. The abrasive material can vary widely, including aluminum oxide, silicon carbide, ceramic, or zirconia alumina, each offering unique properties suited for different applications.

The design of a 150mm sanding disc is crucial for its performance. The diameter of 150mm provides a balanced combination of coverage and maneuverability, making it suitable for both large surface areas and intricate details. Additionally, the center hole design allows for easy attachment to various sanding tools, such as random orbit sanders, orbital sanders, or disc sanders.

Applications

150mm sanding discs find applications across a broad spectrum of industries and tasks. In woodworking, they are used for sanding wooden surfaces, removing paint, varnish, or imperfections, and preparing the wood for finishing. In metalworking, these discs are effective in smoothing metal surfaces, deburring sharp edges, and polishing welds.

Furthermore, 150mm sanding discs are utilized in automotive refinishing for sanding body panels, removing old paint or rust, and achieving a smooth surface before painting. DIY enthusiasts also rely on these discs for various home improvement projects, such as refinishing furniture, restoring decks, or sanding drywall.

Characteristics and Advantages

- Abrasive Grit: 150mm sanding discs are available in a range of grit sizes, from coarse to fine, allowing for versatile use across different materials and applications. Coarser grits are suitable for rapid material removal or leveling uneven surfaces, while finer grits are ideal for achieving smooth finishes and polishing.

- Durability: High-quality 150mm sanding discs are designed to withstand prolonged use and resist wear and tear. The backing material provides stability and support, while the abrasive layers maintain their cutting power and consistency throughout the sanding process.

- Heat Dissipation: Efficient heat dissipation is crucial during sanding to prevent overheating and premature wear of the abrasive material. 150mm sanding discs are engineered with advanced coatings and ventilation systems to minimize heat buildup, ensuring prolonged durability and performance.

- Compatibility: 150mm sanding discs are compatible with a wide range of sanding tools, including handheld sanders, bench sanders, and stationary sanding machines. They can be easily attached and secured to the sanding pad or disc holder, allowing for quick and effortless changes during work.

- Versatility: One of the key characteristics of 150mm sanding discs is their versatility. They can be used on various materials, including wood, metal, plastic, fiberglass, and composites, making them indispensable tools for professionals and hobbyists alike.

Considerations for Optimal Use

While 150mm sanding discs offer numerous advantages, certain considerations should be taken into account to ensure optimal performance and safety:

- Material Compatibility: Select the appropriate abrasive material and grit size based on the material being sanded and the desired finish. Using the wrong abrasive or grit can result in ineffective sanding or damage to the surface.

- Pressure and Speed: Apply consistent pressure and maintain the recommended speed settings when sanding to achieve uniform results and prevent overheating. Excessive pressure or speed can lead to premature wear of the sanding disc and inconsistent finishes.

- Dust Extraction: Use a dust extraction system or wear appropriate respiratory protection to minimize exposure to airborne dust particles generated during sanding. Proper dust extraction not only improves air quality but also enhances visibility and prolongs the life of the sanding disc.

- Storage and Handling: Store 150mm sanding discs in a cool, dry place away from direct sunlight and moisture to prevent degradation of the abrasive material. Handle the discs with care to avoid bending or creasing the backing material, which can affect performance.

Furthermore, the effectiveness of 150mm sanding discs lies not only in their mechanical properties but also in their adaptability to various tasks and environments. Here are some additional aspects to consider:

- Wet vs. Dry Sanding: Depending on the material being worked on and the desired outcome, 150mm sanding discs can be used for wet or dry sanding. Wet sanding is often preferred for materials that generate a significant amount of dust or for achieving a smoother finish without clogging the abrasive. Dry sanding, on the other hand, is suitable for materials that are not affected by water or for tasks where dust control is less of a concern.

- Specialty Discs: In addition to standard abrasive discs, there are specialty 150mm sanding discs available for specific applications. These may include foam-backed discs for contour sanding, film discs for ultra-fine finishing, or abrasive mesh discs for improved dust extraction and longevity. Understanding the unique characteristics of these specialty discs can help users select the most appropriate option for their particular needs.

- Cost vs. Quality: While it can be tempting to opt for the cheapest sanding discs available, it’s important to consider the balance between cost and quality. Investing in high-quality 150mm sanding discs may initially require a higher upfront investment but can ultimately save time and money in the long run by providing superior performance, longer lifespan, and better results. Low-quality discs may wear out quickly, result in uneven finishes, or damage the workpiece, leading to costly rework or replacements.

- Safety Precautions: When using 150mm sanding discs, it’s essential to prioritize safety to prevent accidents and injuries. Wear appropriate personal protective equipment (PPE), such as safety glasses, hearing protection, and gloves, to protect against flying debris, noise, and hand injuries. Follow the manufacturer’s instructions and recommended safety practices for the specific sanding tool and disc being used. Avoid distractions and maintain focus while operating power tools to minimize the risk of accidents.

- Environmental Impact: Consider the environmental impact of using 150mm sanding discs and strive to minimize waste and pollution whenever possible. Choose environmentally friendly abrasive materials and backing materials that are biodegradable or recyclable. Properly dispose of used sanding discs according to local regulations or explore recycling options to reduce landfill waste. Additionally, explore alternative sanding methods or techniques that may be more sustainable or energy-efficient.

Conclusion

In conclusion, 150mm sanding discs possess distinctive characteristics that make them indispensable tools for a wide range of sanding applications. Their composition, design, durability, and versatility make them ideal choices for professionals and DIY enthusiasts seeking efficient and effective sanding solutions. By understanding the characteristics and considerations associated with 150mm sanding discs, users can maximize their performance and achieve superior results in their projects.

Related Products