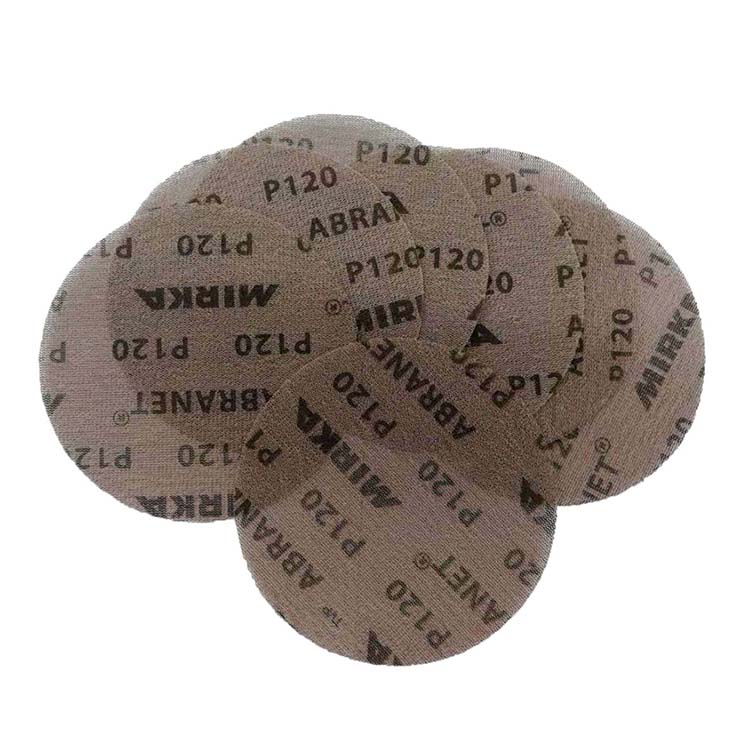

Products Description

-

Premium aluminum oxide mineral is durable, cuts fast, and performs well on many surfaces

-

Strong, C-weight paper backing support aggressive sanding with extra durability compared to lighter-weight paper backings

-

Open-coat construction and load-resistant coating prevent premature loading of the disc surface to maximize cut and extend abrasive life

-

3M™ Hookit™ discs are easy to change and reuse, maximizing sanding utility for the life of the disc

Fine Results for Medium-Coarse Sanding

A grade range from P80 to P180 along with durable C-weight paper backing make our 3M™ Hookit™ Gold Disc 236U 150mm Sanding Disc ideal for auto body sanding projects including rough feather-edging, scratch refinement on bare metal, paint removal around damaged areas, and more. With its open-coat construction and aluminum oxide mineral abrasive, it provides a sharp cut—more aggressive than a comparable closed-coat abrasive of the same grade—without dust accumulating on the disc. The Hookit™ Gold Disc 236U 150mm Sanding Disc is available in 3 or 6-inch diameter sizes for substrates including clear coat, fiberglass, filler, metal, paint, plastic, and putty.

Resists Dust and Debris

Open coat construction means the abrasive grains on our 3M™ Hookit™ Gold Disc 236U 150mm Sanding Discs are placed with space between them to help evacuate sanding dust and other debris to avoid clogging the cutting edge of the grains. The load-resistant coating on the abrasive grains also allows the disc to continue cutting even when sanding paints, fillers, putties, and other materials that would otherwise clog the disc and hinder sanding ability. All of this adds up to increased productivity and reduced material consumption.

The 6-hole pattern on select versions of the 3M™ Hookit™ Gold Disc 236U facilitates dust evacuation, especially when used with a vacuum system. This design doesn’t even require the alignment of holes with the disc pad, making disc changes quick and simple.

7-hole pattern on select versions facilitates dust evacuation

About Aluminum Oxide Abrasive

Aluminum oxide is popular among industrial professionals because of its fast cut rate and long life. This mineral makes a tough, durable abrasive that self-fractures to expose fresh cutting edges, whereas traditional natural abrasives dull more quickly. Due to its fast cut rate, hardness, and strength, it is widely used in grinding applications in addition to sanding and finishing applications. Aluminum oxide is suitable for a wide variety of materials in metalworking, including ferrous alloys, for auto body applications.

About Our Hookit™ Attachment System

3M offers a complete line of hook-and-loop style Hookit™ 150mm sanding discs for work spaces where adhesive-backed discs may become contaminated by dust, dirt, or flying debris. Hookit™ sanding discs conveniently and firmly attach to a hook-and-loop backup disc pad (sold separately) on a random orbital sander, can be removed cleanly and easily, and can be re-used again and again for the extent of the abrasive life.

Durable from Front to Back

Through a combination of science and strength—from the grain to the back-up disc pad attachment—our 3M™ Hookit™ Gold Disc 236U delivers long disc life, a consistently sharp cut, and superior dust resistance for better auto body operations.

3M™ Hookit™ Paper Disc 236U 150mm Sanding Disc offers aggressive cut and long life on a premium aluminum oxide disc with a durable edge and convenient Hookit™ attachment. A go-to product in many industrial operations, this durable disc is well suited for high-production sanding operations as well as general-purpose applications on paint, primer, wood, metal, plastic, and composites, including fiberglass.

Designed for use with a random orbital sander, the strong C-weight paper backing on our 3M™ Hookit™ Paper Disc 236U resists tearing and edgewear during aggressive sanding, and the disc is resin-bonded for heat resistance, further increasing life and cut. These 150mm sanding discs also feature an open coat and a load-resistant coating to enhance dust management and cut-rate.

A load-resistant coating allows the disc to continue cutting even when sanding softwoods, paints, and other materials that would otherwise clog the surface of the disc and hinder sanding ability. Loading is further reduced by an open coat, which means the abrasive grains are spaced slightly apart so that dust can escape rather than obstructing the cutting edge of the grains, thereby optimizing cut-rate and disc life.

150mm sanding discs come in a variety of forms to fit various power tools and disc pads. We designed the 3M™ Hookit™ Paper Disc 236U to conveniently and firmly attach to a hook-and-loop backup disc pad (sold separately) on a random orbital sander, to be removed cleanly and easily, and to be simple to reuse. A load-resistant coating prevents wood dust, paint particles, and other debris from prematurely clogging the surface of the disc, optimizing cut-rate and disc life.

The 3M 150mm sanding disc 236U is made of aluminum oxide abrasive with excellent grinding power and durability. During rough processing, use temperature-resistant resin glue and a stronger base material to give full play to the durability of this product. In finishing, using a soft and elastic base material can produce a smoother surface. The clogging coating on the surface can avoid abrasive clogging and maximize the performance of the product.

3M 236U sandpaper is used in the woodworking market for rough and fine sanding of the surface of plain boards, sanding of sapwood on plain boards, and sanding of special-shaped surfaces. It can be used with square vibrating machines and disc eccentric vibrating grinders.

Uses: grinding in the car’s intermediate paint or primer workshop, removing foreign matter and surface particles, deburring sharp edges, and surface adjustment of plastic products after molding.

What makes this product special?

- Adhesive backing allows for quick application and easy removal

- Convenient disc rolls eliminate the need to remove disc liners from individual discs

- Strong, C-weight paper backing provide extra durability when compared to lighter-weight paper backings

- Aluminum oxide is durable, cuts fast, and performs well on many surfaces

- Load-resistant coating helps prevent premature loading of the disc surface to maximize cut and extend the life of the abrasive grains

- Selected ore sand provides a longer-life fiber paper backing, and high-density sand planting provides better cutting capacity.

- Has a pressure-sensitive adhesive or velvet backing for easy loading and unloading;

- The anti-clogging coating is specially treated to effectively avoid sand and dust clogging.

Product detail & Main specification

|

Abrasive Material |

Aluminum Oxide |

|

Alternative Sale Availability |

This item is for industrial use only, and there are no VOC restrictions. |

|

Application |

Finishing, Grinding, Sanding, and Preparation |

|

Attachment Type |

Hook & Loop |

|

Backing Material |

Paper |

|

Backing Weight |

C Weight |

|

Brand |

Hookit™ |

|

Coat Type |

Open Coat |

|

Color Family |

Yellow |

|

Equipment – Machines |

Random Orbital Sanders |

|

Form Type |

Hookit™ |

|

For Use On |

Aluminum, Carbon Steel, Composites, Glass, Paint |

|

Grit |

P100, P120, P150, P180, P220, P240, P320, P400, P500, P80 |

|

Hole Configuration |

500X, 600Z |

|

Industries |

Aerospace, AOEM, Composite, Cutting Tool Manufacturing, Marine, Metalworking, Paint Preparation, Transportation & Heavy Equipment |

|

Maximum Speed |

12000 rpm |

|

Overall Diameter (Metric) |

127 mm, 152.4 mm |

|

Position |

Better |

|

Substrate |

Aluminum, Carbon Steel, Composite, Glass, Paint |

Product application

The 150mm sanding disc represents a circular abrasive tool designed for sanding, smoothing, shaping, and finishing various surfaces. Its diameter of 150mm provides an optimal balance between coverage area and maneuverability, making it a favored choice across different industries for achieving precise and uniform surface finishes.

These discs are crafted from high-quality abrasive materials, such as aluminum oxide, zirconia alumina, ceramic alumina, or silicon carbide, bonded to a robust backing material. This construction ensures durability, efficient material removal, and consistent performance throughout their lifespan.

Key Features and Advantages

1. Enhanced Efficiency

The 150mm sanding discs excel at expediting surface preparation tasks. Their larger diameter allows for a more extensive coverage area, enabling quicker material removal while maintaining precision. This enhanced efficiency translates to reduced labor time and increased productivity across various industrial applications.

2. Precision and Consistency

Achieving a uniform surface finish is paramount in many industries. The 150mm sanding discs deliver consistent results due to the even distribution of abrasive grains across the disc’s surface. This feature, combined with controlled movements during sanding, ensures precise material removal, enabling operators to achieve desired surface qualities with consistency.

3. Versatility Across Applications

These discs exhibit remarkable versatility and adaptability across a spectrum of applications. Whether it’s removing imperfections, refining weld seams, blending surfaces, or preparing materials for coatings, the 150mm sanding discs offer a versatile solution suitable for various materials, including metals, wood, plastics, and composites.

4. Longevity and Durability

Manufactured with durability in mind, these discs are engineered to withstand rigorous applications without compromising performance. The high-quality abrasive materials and robust backing ensure longevity, reducing the need for frequent disc replacements and minimizing overall maintenance costs.

5. Heat Dissipation and Cooling

Heat build-up during surface preparation can negatively impact both the tool and the material being worked on. Many 150mm sanding discs are designed with advanced cooling features that dissipate heat effectively, preventing damage to sensitive materials and extending the lifespan of the discs.

Applications Across Industries

1. Metalworking and Fabrication

In metalworking and fabrication industries, these discs are instrumental in preparing metal surfaces for welding, polishing, deburring, and finishing. They play a crucial role in achieving the desired surface qualities for various components, ensuring both aesthetic appeal and functional integrity.

2. Woodworking and Carpentry

Woodworkers rely on 150mm sanding discs for shaping, smoothing, and refining wooden surfaces. From sanding large wooden panels to intricate detailing, these discs offer the precision and consistency needed for high-quality woodworking projects.

3. Automotive and Aerospace

The automotive and aerospace industries demand precise surface finishes for vehicle components and aircraft parts. 150mm sanding discs aid in achieving the required surface qualities, ensuring optimal performance, durability, and aesthetics in these critical applications.

4. Construction and Renovation

Builders and contractors utilize these discs for surface preparation tasks in construction and renovation projects. Whether it’s smoothing concrete, preparing surfaces for painting, or removing old finishes, the discs contribute to achieving desired surface textures and qualities.