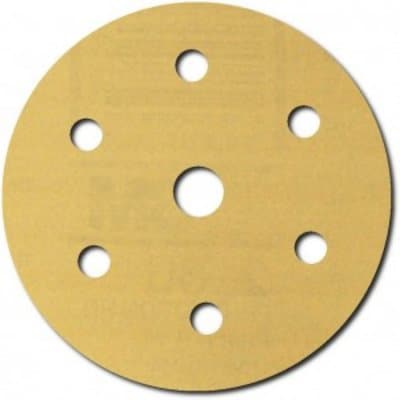

A 150mm sanding disc is a circular abrasive tool used for sanding or removing material from a surface. It typically has a diameter of 150mm (5.9 inches) and is designed to be used with a power tool such as a orbital sander or angle grinder. The disc is made of abrasive material, such as aluminum oxide or silicon carbide, and is attached to a backing material, such as paper or cloth, which is held onto the disc by adhesive. The abrasive particles on the disc remove material from the surface as the disc spins, creating a smooth, even surface.

Application field of 150mm sanding disc

A 150mm sanding disc is commonly used in woodworking and metalworking applications for sanding and smoothing surfaces. Some specific application fields where it is used include:

- Woodworking: 150mm sanding discs are used to smooth and finish surfaces of wood furniture and other wood products. They can also be used to remove rough spots and even out surface imperfections.

- Metalworking: They are used to remove rust, paint, and other surface coatings from metal surfaces and to smooth and finish metal surfaces in automotive and metal fabrication.

- Automotive Industry: 150mm sanding discs are used for sanding, polishing, and finishing surfaces on cars, trucks, and other vehicles, as well as for removing paint, rust, and other surface coatings.

- Construction: 150mm sanding discs can be used to smooth and finish surfaces on concrete, drywall, and other building materials.

- Surface preparation: 150mm sanding disc is used for surface preparation of various materials, such as metal and plastic surfaces, before paint or coating application.

- DIY projects: Can also be used for various DIY projects such as sanding of decks and floors, and remodeling.

Advantages of using 150mm sanding disc

There are several advantages to using a 150mm sanding disc in woodworking and metalworking applications, including:

- Speed: A larger sanding disc like 150mm can cover a greater surface area in a shorter amount of time, making it a more efficient option for large-scale sanding projects.

- Aggressiveness: The 150mm disc is more aggressive and faster than a smaller disc, and can remove material quickly, making it a good option for removing rust, paint and other surface coatings.

- Versatility: 150mm sanding discs can be used for various applications and can be used with a variety of materials, such as wood, metal, plastic, and composites.

- Precision: 150mm sanding discs can be attached to various machines and can be adjusted for speed and pressure, this allows for more precise control and a better finish.

- Variety of Grit: 150mm sanding disc are available in variety of grit ranges, from coarse to fine, so it can be used on a variety of materials, surfaces, and stages of the sanding process.

How to maintain 150mm sanding disc

To maintain a 150mm sanding disc, you should follow these steps:

- Clean the disc thoroughly before and after each use. This will remove any debris or dust that has accumulated on the disc, which can clog the abrasive surface and reduce its effectiveness.

- Check the disc for any signs of wear or damage, such as cracks, tears, or excessive abrasions. If the disc is damaged, it should be replaced to ensure safety and prevent poor performance.

- Store the disc in a cool, dry place when not in use. Exposure to high temperatures or humidity can cause the disc to warp or become brittle, which can lead to damage or breakage.

- Follow the manufacturer’s recommendations for the appropriate speed and pressure when using the disc. Using too much pressure or speed can cause the disc to wear out faster, or even cause damage to the workpiece.

- Follow safety precautions when using the disc. Sanding discs can be dangerous if not used properly. Wear protective gear and use the disc in accordance with the manufacturer’s instructions.

What are the materials of 150mm sanding disc

150mm sanding discs are typically made of abrasive materials that are adhered to a backing plate or pad. The abrasive material is the part of the disc that does the actual sanding. The most common types of abrasive materials used in sanding discs are:

- Aluminum oxide: This is a common abrasive that is made from aluminum oxide crystals. It is hard, durable, and resistant to heat, making it suitable for a wide range of sanding applications.

- Silicon carbide: This abrasive is made from silicon carbide crystals and is harder and more brittle than aluminum oxide. It is typically used for sanding harder materials, such as metal and ceramics.

- Zirconia alumina: This abrasive is made by mixing zirconia and aluminum oxide, resulting in a more durable abrasive that can withstand heavy use.

- Ceramic alumina: This abrasive is made from ceramic and aluminum oxide, it offers a strong durability and longevity.

The backing plate is typically made of materials such as paper, cloth, or foam. These materials help to hold the abrasive in place and provide a flexible, conformable surface for sanding. The quality of the abrasive and the backing plate can affect the disc’s sanding performance and lifespan.

Zhuhai Xinhongrui Abrasives is a leading abrasive tool supplier in Guangzhou, China. We have advanced technology and excellent product quality, our products mainly include zirconium corundum, mesh sanding discs, sanding sponge, 3m cubitron and so on. Our factory consists of four areas: production machinery, raw materials, product packaging and warehouse. Each area is supervised by a special person to ensure that the production process is error-free. Welcome to visit us.

Related Products