Products Description

- With permanently sharp, microreplicated 3M™ 466LA Trizact abrasives for reproducible and consistent results

- Ideally suited for the two-step 3M repair process for repairing damage to vehicle paintwork

- Supplied on a handy roll with self-adhesive discs

- It can be used very well with mini eccentric sanders or orbital sanders

- Carrying out repairs quickly and efficiently

Faster Cut, Longer Life

The secret behind the longer life and faster cut of our 3M trizact sanding discs lies in the precise, microreplicated system of channels that move sanding debris away from the disc. This prevents debris from building up between the abrasive structures, allowing fresh minerals to be continually exposed to the workpiece.

Consistent Performance and Quality

Unlike conventional abrasives, 3M™ 466LA Trizact abrasive starts sharp and stays sharp, resulting in more predictable finishes and improved, consistent quality. 3M™ 466LA Trizact abrasive discs can last up to five times longer than conventional discs and provide precise finish control. Three-dimensional structures uniformly distributed over the entire surface of Trizact abrasives ensure consistent performance and eliminate disc-to-disc variation.

Great for Paint/Clear Coat Defect Repair

Our film discs are perfect for finishing, defect repair, and leveling when you’re working on paint, a clear coat, or plastic defect removal. The precisely graded mineral helps reduce processing steps and produces a high gloss level. Very little water is needed, making the process easy and efficient. The extended life of the film disc, paired with its fast and consistent cut, make it the perfect aid for speedy repairs.

The three-dimensional structures of 3M™ 466LA Trizact abrasives contain multiple layers of mineral. As these pyramid-like structures wear, fresh, sharp minerals are constantly exposed to the workpiece, resulting in faster, more consistent cutting.

Hand Sanding

- Level or remove the defect using a 3M™ Finesse-it™ Hand Pad and a 466LA disc

- Spray the 466LA disc with water to prevent the abrasive from loading during sanding

- Sand the defect for 3 to 5 seconds, depending on its size

- Wipe the area clean with a Scotch-Brite™ high-performance cloth.

Recommended Applications

- Ideally suited for the two-step 3M repair process for repairing damage to vehicle paintwork

- Use with orbital or mini random orbital sanders to create a polish-ready surface

Product detail & Main specification

|

Abrasive Material

|

Silicon Carbide

|

|

Application

|

Finishing, Polishing

|

|

Attachment Type

|

PSA

|

|

Backing Material

|

Film

|

|

Backing Thickness (Imperial)

|

3 mil

|

|

Brand

|

Trizact™

|

|

Color Family

|

Gray

|

|

Equipment – Machines

|

Random Orbital Sanders

|

|

Health and Safety

|

Eye Protection, Hand Protection, Head and Face Protection, Hearing Protection

|

|

Industries

|

AOEM, Paint Preparation, Transportation & Heavy Equipment

|

|

Micron Grade

|

A5

|

|

Overall Diameter (Imperial)

|

1.25 in

|

|

Overall Diameter (Metric)

|

31.75 mm

|

|

Product Color

|

Gray

|

|

Product Form

|

Disc

|

|

Substrate

|

Clear Coat, Paint, Topcoat

|

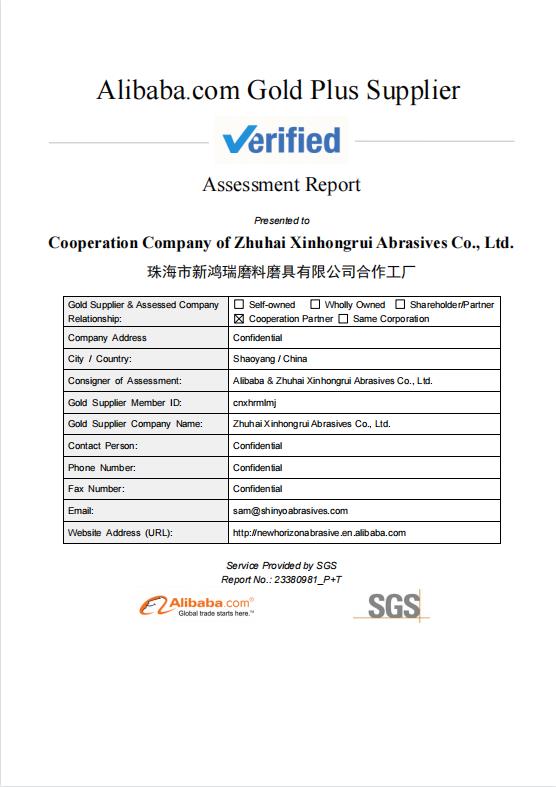

Certificate

When it comes to sanding and finishing, precision and efficiency are key. Whether you’re a professional woodworker, an automotive enthusiast, or a DIY home improvement enthusiast, achieving the perfect surface is essential. This is where 3M Trizact Sanding Discs shine. With their revolutionary technology and unmatched quality, these sanding discs are the go-to choice for those who demand the best in their projects.

What are 3M Trizact Sanding Discs?

3M Trizact Sanding Discs are advanced abrasive tools designed to deliver exceptional results in sanding and finishing applications. They are part of 3M’s extensive range of high-quality abrasives and have become a preferred choice for professionals and enthusiasts alike. These discs are engineered to provide consistent, reliable, and superior performance throughout their lifespan, making them a valuable addition to any sanding and finishing toolkit.

The Trizact Difference

What sets 3M Trizact Sanding Discs apart from conventional abrasives is the innovative technology they incorporate. Trizact technology represents a breakthrough in abrasive materials, offering numerous advantages that are unparalleled in the industry. Let’s delve into what makes these sanding discs so special:

-

Consistency: Trizact abrasives are renowned for their remarkable consistency. This means that the abrasive material maintains a uniform level of cutting power as it wears down. Traditional abrasives can become less effective over time as they wear unevenly, leading to inconsistencies in the finished surface. With Trizact, you can expect a consistently smooth and even result from start to finish.

-

Microreplication: The key to Trizact’s performance lies in its microreplication technology. These discs feature precisely engineered, pyramid-like structures that are evenly distributed across the abrasive surface. These pyramids contain abrasive material, which is exposed as they wear down during use. This controlled release of abrasive material ensures that the cutting action remains constant, preventing over-aggressive sanding and reducing the risk of swirl marks and uneven surfaces.

-

Longevity: Due to the even wear pattern and controlled release of abrasive material, 3M Trizact Sanding Discs tend to last significantly longer than traditional abrasives. This means fewer disc changes and more efficient use of your time and resources.

-

Enhanced Efficiency: The consistent performance and longevity of Trizact abrasives translate into improved efficiency. Whether you’re sanding wood, metal, or composite materials, you can count on these discs to deliver excellent results with fewer passes, reducing the time and effort required for your projects.

-

Versatility: 3M Trizact Sanding Discs are available in a wide range of grits and sizes to suit various applications. Whether you need to remove material quickly, refine a surface to a mirror-like finish, or something in between, there’s a Trizact disc that’s perfect for the job.

Applications of 3M Trizact Sanding Discs

These exceptional sanding discs find applications in a multitude of industries and are essential tools for various projects. Here are some of the key areas where 3M Trizact Sanding Discs excel:

-

Woodworking: Whether you’re working on furniture, cabinetry, or intricate wood crafts, Trizact discs provide the precision and consistency needed for a perfect finish. They are ideal for sanding wood surfaces, eliminating imperfections, and achieving a smooth, flawless result.

-

Automotive: Trizact discs are a favorite among automotive professionals and enthusiasts. They are perfect for smoothing out imperfections in paint, clear coats, and metal surfaces, ensuring that your car’s finish looks its best. They are also highly effective for removing oxidation and blemishes from headlights and taillights.

-

Metalworking: When it comes to metal fabrication and finishing, Trizact discs offer unparalleled performance. They excel at removing weld seams, refining metal surfaces, and preparing materials for painting or coating. With these discs, you can achieve a precise and professional finish on various metals, including stainless steel and aluminum.

-

Marine Industry: For boat owners and professionals in the marine industry, maintaining the appearance and durability of vessels is paramount. 3M trizact sanding discs are the ideal choice for restoring and finishing gel coat surfaces, as well as removing corrosion and rust from metal components.

-

Composite Materials: Trizact technology is well-suited for sanding and finishing composite materials used in aerospace, automotive, and other industries. These 3m trizact sanding discs provide the precision and consistency required for critical applications where material integrity and aesthetics are of utmost importance.

Selecting the Right Trizact Disc

3M offers a diverse range of 3M trizact sanding discs to meet the specific needs of different applications. When choosing the right Trizact disc for your project, consider the following factors:

-

Grit Size: Trizact discs are available in various grit sizes, ranging from coarse to fine. Coarser grits are suitable for rapid material removal, while finer grits are used for smoothing and finishing. Select the grit size that aligns with your project goals.

-

Size and Shape: Trizact discs come in different shapes and sizes, including round, square, and rectangular configurations. Choose the disc shape and size that best suit your sanding and finishing tools and the contours of your workpiece.

-

Application: Consider the specific material and application for which you’re using the 3m trizact sanding discs. Some discs are optimized for wood, while others are more suitable for metal or composite materials. Make sure you select the appropriate disc for the job.

-

Backing Type: Trizact discs are available with various backing types, including adhesive-backed and hook-and-loop (Velcro) options. The choice of backing type depends on your sanding equipment and personal preference.

Tips for Using 3M Trizact Sanding Discs

To get the best results with 3M Trizact Sanding Discs, consider the following tips:

-

Proper Sanding Technique: Ensure that your sanding technique is consistent and even to maximize the benefits of Trizact’s microreplication technology. Apply even pressure and maintain a steady, controlled pace to achieve the best finish.

-

Dust Management: Sanding can generate a significant amount of dust. Use appropriate dust extraction systems, masks, and eye protection to keep your workspace clean and safe.

-

Start with the Right Grit: Begin with a coarser grit to remove imperfections and progress to finer grits for a smoother finish. Avoid skipping grits to achieve the best results.

-

Sanding Lubrication: In some applications, using water or a lubricating solution can improve the performance of 3m trizact sanding discs. Be sure to follow the manufacturer’s recommendations for lubrication, especially when working with finer grits.

-

Disc Maintenance: Keep an eye on your Trizact disc’s wear pattern. When the pyramids are worn down, it’s time to replace the disc to maintain consistent performance.

-

Safety First: Always follow safety guidelines when using 3m trizact sanding discs. Wear appropriate personal protective equipment, including eye protection, dust masks, and hearing protection, as needed.