Products Description

- Part of the 3M™ Perfect-It™ Paint Finishing System for high gloss and deep color paint finishes

- Ideal for refining sand scratches to help reduce the amount of time spent compounding

- Patterned, precise mineral structures provide a combination of fast cutting and consistent finish

- Long-lasting, even-wearing abrasive can reduce or eliminate extra materials and even full stages in specific cases

3M Trizact 3000 abrasive discs are ideal for stretching, activating paints, and curing varnishes before polishing. They give the perfect combination of a fast and consistent cut. They also reduce operator fatigue and polishing time. They are ideal for stainless steel applications and are used in dual-action roto-orbital sanders with interface or manual hookit support. How to use: Discs with machines: Clean the surface and, if necessary, degrease it properly. After the standard sanding recommended by 3M for automotive varnishes, clean the workpiece by removing waste from sanding.

Foam discs are used in a spot repair system for removing P1200-P1500-grade sand scratches before using the 3M Trizact 3000 Perfect-It™ Panel Repair System.

Patterned, precise mineral structures give Trizact™ abrasives the combination of a fast cut and a consistent finish every time. Use P1000 foam blending discs for scuff-sanding blend panels prior to painting. Use P1500 clearcoat sanding discs for leveling dust nibs and sanding mismatched orange peel. Finally, use a P3000 foam disc for removing P1200-P1500-grade sand scratches prior to using the 3M Trizact 3000 Perfect-It™ polishing system. Foam discs are used in a spot repair system for removing sanding scratches before using a rubbing compound.

Advanced Abrasives for Collision Repair

As part of our Perfect-It™ Paint Finishing System, 3M™ Trizact™ Hookit™ Foam Abrasive Discs help reduce the time and material required for compounding, creating significant operating efficiencies during spot and large panel repairs. Our Trizact™ abrasives remove fine-grade sand scratches while staying sharper longer, reducing material costs. In specific situations, the abrasive allows operators to reduce or eliminate additional materials, like wool compounding pads. They can also save time by reducing and even eliminating entire grade sequences, such as compounding, for more efficient operations. Foam backing provides plenty of control and consistent contact with the surface, making it great for preserving orange peel. Trizact technology in the form of nanoparticles performs uniform and effective sanding. Micropyramids progressively increase in abrasiveness as they wear out more pyramids, so they do not lose effectiveness until they wear out.They can be used for dry sanding or better water, as well as with quick detailer-type lubricants. They are resistant, durable, and safe for painting if used properly. They can be washed for later use. After use, it is advisable to continue with a softer sanding and subsequent polishing to recover the shine of the paint. These sandpapers are the choice of thousands of professionals in brass and painting workshops. It can be used by hand or with a sanding machine. Its thickness is like a sheet of paper; therefore, it is necessary to use a fluffy adapter with the plate to achieve a constant and uniform sanding.

Features:

- Ideal for refining sand scratches to help reduce the amount of time spent compounding.

- Patterned, precise mineral structures provide a combination of a fast cut and a consistent finish.

- Long-lasting, even-wearing abrasives can reduce or eliminate extra materials and even full stages in specific cases.

- The Hookit attachment system allows for fast, easy change-outs with Hookit disc pads and soft interface pads.

About Our Trizact™ Abrasives

For more predictable finishes and improved, consistent quality, 3M Trizact 3000 products feature 3-dimensional structures that are uniformly distributed over the surface of the abrasive. These patterned, precise mineral structures contain multiple layers of abrasive minerals. As the structures wear, fresh, sharp minerals are exposed. The result is that the abrasive cuts faster, allows for precise finish control, and stays sharper longer—operators can even reduce grade sequences during collision repair, requiring fewer process steps and fewer abrasive products.

This condition will allow better use of the Trizact P3000 disc. With a dual-action sander and interface, work on the area until the surface looks semi-glossy with low roughness. Make cross-movements of overlap on the piece. Always make vertical and horizontal movements, or vice versa. Repeat these movements four to six times in the piece. Reduce the speed of the sander by between 40 and 50% of its totality for better performance on Trizact P3000 discs. Discs Manually: clean the surface and, if necessary, degrease properly. After the standard sanding recommended by 3M for automotive varnishes, clean the workpiece by removing waste from sanding.

The main application of 3M Trizact 3000 discs is to reduce the roughness level of the previous step, but nothing prevents that; regardless of the quality, type, technology, and condition of the varnish, its application is done without any previous sanding. the surface to be worked in such a way as to notice a small foaming during the sanding process. This condition will allow better use of the 3M Trizact 3000 disc. Using Hookit manual support, secure the disc and work on the area until the surface looks semi-glossy and low in roughness. With moderate pressure, make circular overlay movements on the workpiece. Always make vertical and horizontal movements, or vice versa. Repeat these movements four to six times on the workpiece.

3M 02085 is a structured abrasive that features an engineered surface of microscopic, three-dimensional structures. This precise abrasive surface is ideal for automotive paint finishing applications requiring a consistent and fine finish.

Patterned, precise mineral structures give Trizact abrasives the combination of a fast cut and a consistent finish every time. Use P1000 foam blending discs for scuff-sanding blend panels prior to painting. Use P1500 clearcoat sanding discs for leveling dust nibs and sanding mismatched orange peel. Finally, use a P3000 foam disc for removing P1200-P1500-grade sand scratches prior to using the 3M Perfect-It polishing system. Foam discs are used in a spot repair system for removing sanding scratches before using a rubbing compound.

The 3M Trizact 3000 Foam Sand Disc removes fine sand marks from painted surfaces, reducing compounding time. The three-dimensional mineral grinding structure is evenly distributed on the entire surface of the sand disc and can be worn evenly to obtain a uniform surface effect, a longer life of the sand disc, and a lower material cost. Foam-backed discs are part of the 3M™ Perfect-It™ Painting System.

Note:

- The actual color of the project may be slightly different from the image displayed on the website, which is caused by factors such as the brightness of the display.

- Please allow the measurement data to be slightly biased.

Product detail & Main specification

|

Abrasive Material |

Silicon Carbide |

|

Application |

Repairing Large Area Paint Defects |

|

Attachment Type |

Hook & Loop |

|

Brand |

Trizact™ |

|

Case Quantity |

4 Cartons per Case |

|

Color Family |

Gray |

|

Grit |

P3000 |

|

Overall Diameter (Imperial) |

6 in |

|

Overall Diameter (Metric) |

150 mm |

Product Color |

Gray |

|

Product Form |

Disc |

Product application

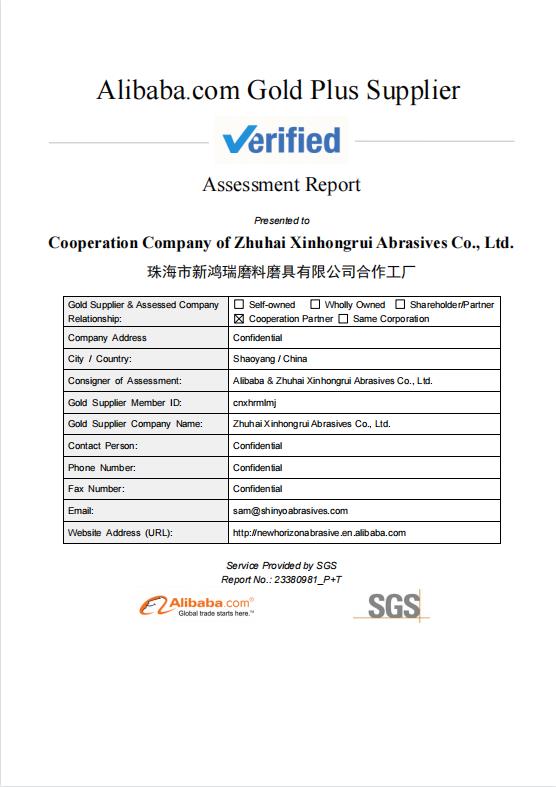

Certificate

Features:

The 3M Trizact 3000 boasts an array of features that set it apart as an industry-leading abrasive product:

-

Precisely Engineered Abrasive Structure: The 3m trizact 3000 utilizes a unique and precisely engineered abrasive structure that offers exceptional consistency and uniformity in abrasive performance. This structure is designed to deliver a consistent cut rate and finish, ensuring that every project meets the highest standards of quality.

-

Long-Lasting Durability: Designed to last, the Trizact 3000 is built to withstand the demands of professional use. Its durable construction ensures that it won’t break down or wear out prematurely, saving you time and money on replacement products.

-

Micron-Graded Abrasive Particles: The abrasive particles in the 3m trizact 3000 are micron-graded, which means they are uniform in size and distribution. This results in a finer finish with fewer deep scratches or imperfections, making it an ideal choice for critical finishing applications.

-

Film Backing: The film backing of the Trizact 3000 offers excellent flexibility, which is particularly valuable when you’re working on contoured or curved surfaces. This feature allows for consistent contact with the workpiece, ensuring even and smooth finishing.

-

Structured Abrasive Technology: The 3M trizact 3000 incorporates 3M’s proprietary Structured Abrasive Technology. This technology allows the abrasive structure to stay sharp, maintaining consistent performance over the product’s lifespan.

-

Advanced Coating: The abrasive particles are coated with a high-quality resin that enhances their longevity and provides excellent heat resistance. This results in cooler cutting and prevents premature abrasive breakdown.

-

Hook-and-Loop Attachment: The 3m trizact 3000 features a convenient hook-and-loop attachment system that makes changing abrasive discs quick and easy. This system also provides a secure and reliable connection during use.

Benefits:

The 3M Trizact 3000 offers a range of benefits to users across different industries and applications:

-

Consistent Finish: The precision-engineered abrasive structure ensures that you achieve a consistent finish every time. Whether you’re sanding, polishing, or refining surfaces, the Trizact 3000 delivers a uniform result that meets the highest quality standards.

-

Improved Productivity: With its long-lasting durability and sharp abrasive particles, the 3m trizact 3000 allows you to work more efficiently. You’ll spend less time changing abrasive discs and more time completing your projects.

-

Exceptional Versatility: The 3m trizact 3000 is suitable for various materials, including metals, plastics, wood, and automotive finishes. Its versatility makes it a valuable tool for professionals in multiple industries.

-

Reduced Material Consumption: The 3m trizact 3000’s Structured Abrasive Technology results in less wear and tear on the abrasive, reducing material consumption and minimizing waste.

-

Enhanced Operator Comfort: The film backing and flexible construction of the Trizact 3000 provide an ergonomic and comfortable sanding experience, reducing operator fatigue and strain.

-

Improved Surface Quality: The micron-graded abrasive particles, combined with the advanced coating, result in a finer finish with fewer imperfections and swirl marks. This is particularly beneficial for applications where surface quality is paramount.

Applications:

The 3M Trizact 3000 is a versatile abrasive product with a wide range of applications across various industries. Here are some of the key areas where the Trizact 3000 excels:

-

Automotive Refinishing: Whether you’re polishing paint surfaces, removing imperfections, or finishing clear coats, the Trizact 3000 is an invaluable tool for achieving a professional finish in automotive refinishing applications.

-

Woodworking: Woodworkers can benefit from the 3m trizact 3000 when sanding and finishing wood surfaces, furniture, and cabinetry. Its precision and consistency help achieve the desired results.

-

Metal Fabrication: In metal fabrication, the Trizact 3000 is ideal for grinding, blending, and finishing metal surfaces. Its durable construction can withstand the rigors of metalworking.

-

Plastic Fabrication: When working with plastics, the 3m trizact 3000’s precision abrasive structure ensures a smooth and consistent finish on plastic components and products.

-

Marine and Boat Refinishing: Marine and boat professionals can rely on the Trizact 3000 for tasks such as gel coat repair, surface preparation, and finishing on boat surfaces and fiberglass.

-

Aerospace: The 3m trizact 3000 is valuable in aerospace applications, such as the finishing and repair of aircraft components and surfaces. Its consistency and precision are essential in this critical industry.